Welcome To Unique Facade Aluminum Works

Mussafah, Abu Dhabi - United Arab Emirates

Call Us

Mail Us

Follow Us

How We Work

WHAT WE DO

How We Work

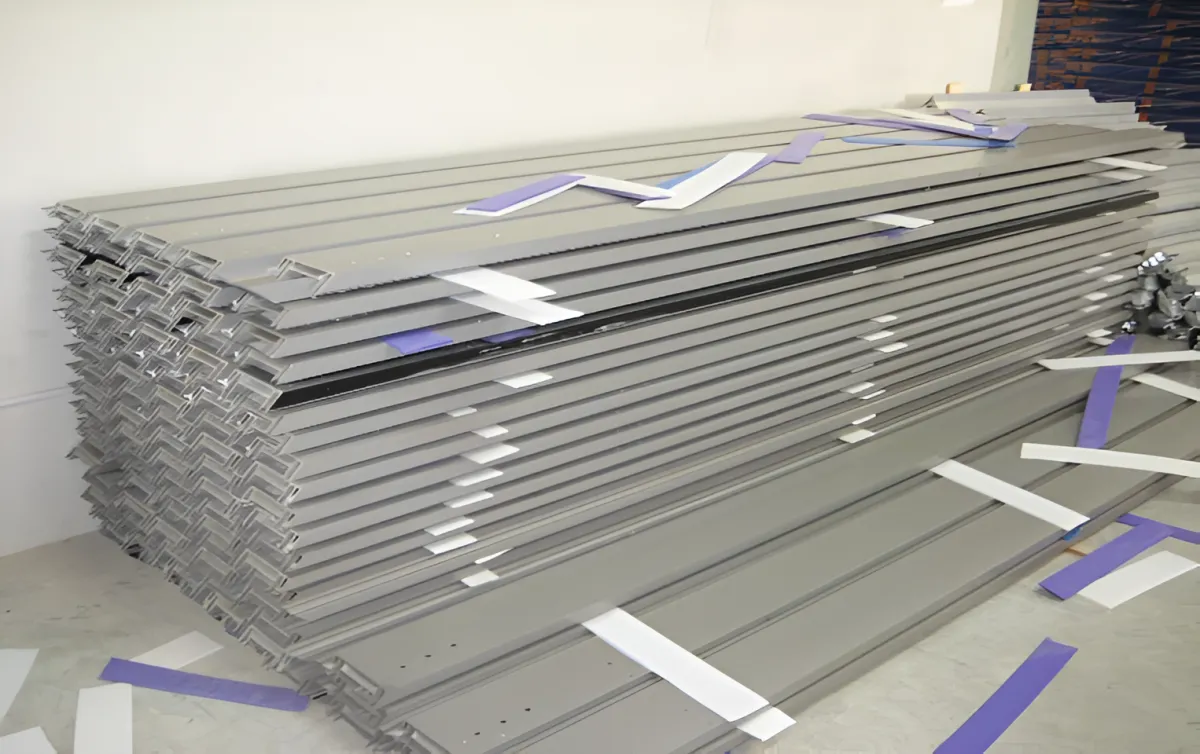

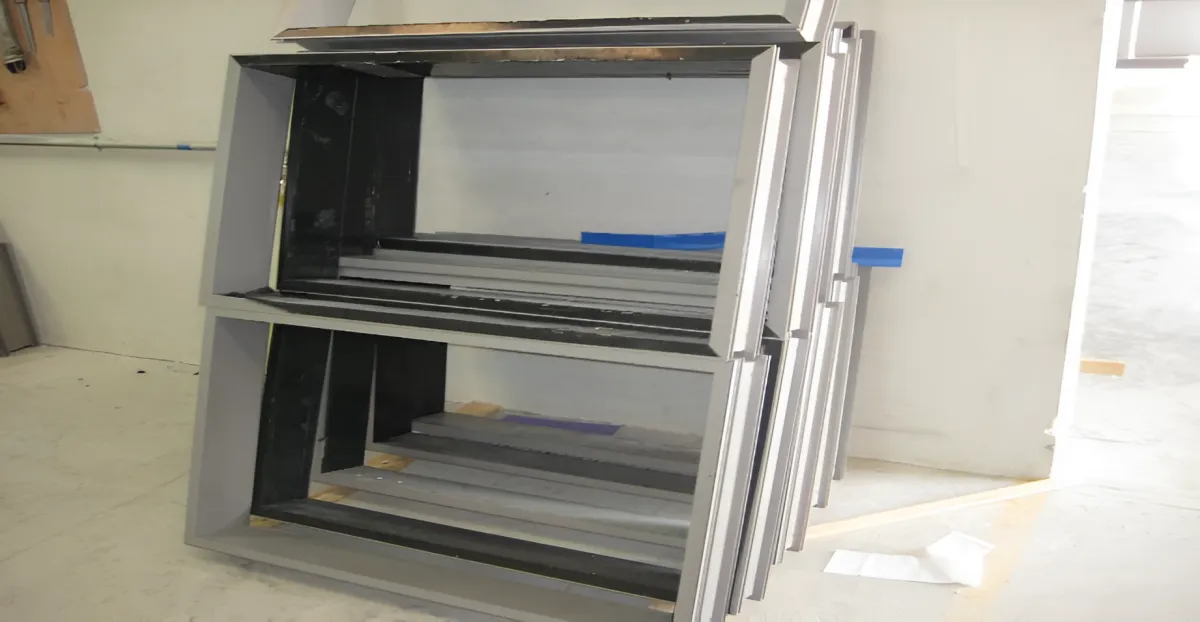

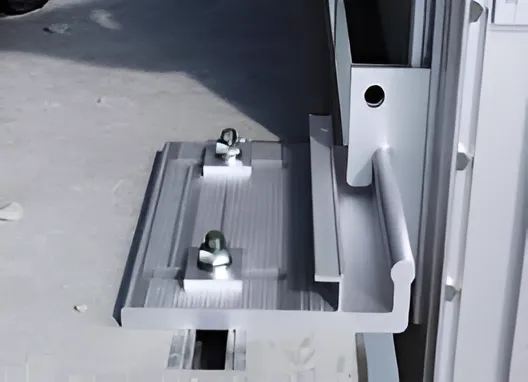

1. Fabrication And Assembly Of The Main Frame

Fabrication of the main frame in the assembly line is very important, to maintain the panel’s correct dimension & diagonal measurements.

Panels are ready in assembly for fixing backpan and accessories.

2. Bonding Of The Glass And Curing Of The Panel In Conveyor Area

What is the bonding and structure of silica?

Silicon dioxide (often called silica) is the main compound found in sand. It is an example of a substance with a giant covalent structure. It contains many silicon and oxygen atoms. All the atoms in its structure are linked to each other by strong covalent bonds.

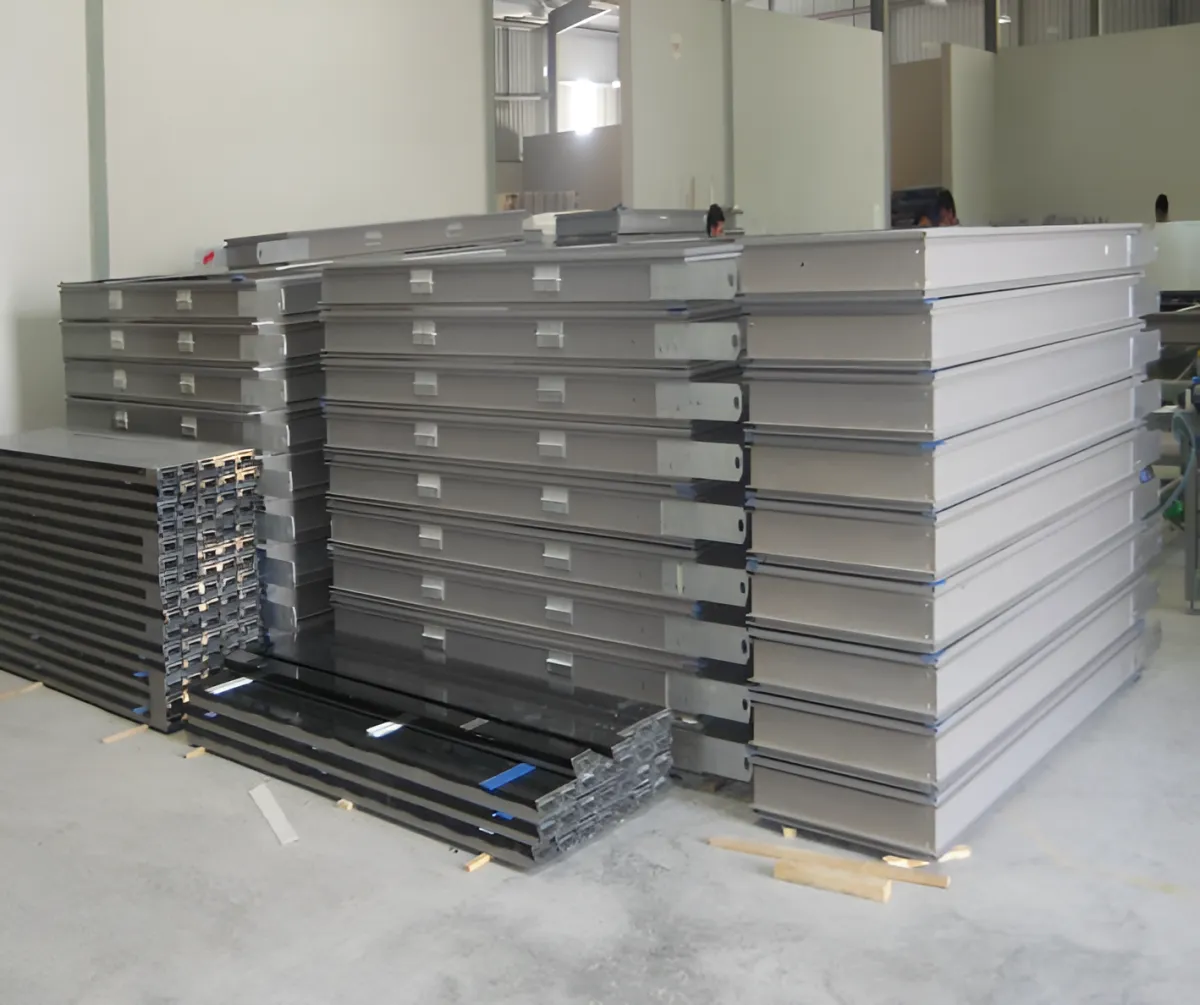

3. Arranging The Panel By Sequence Number In The Pallet

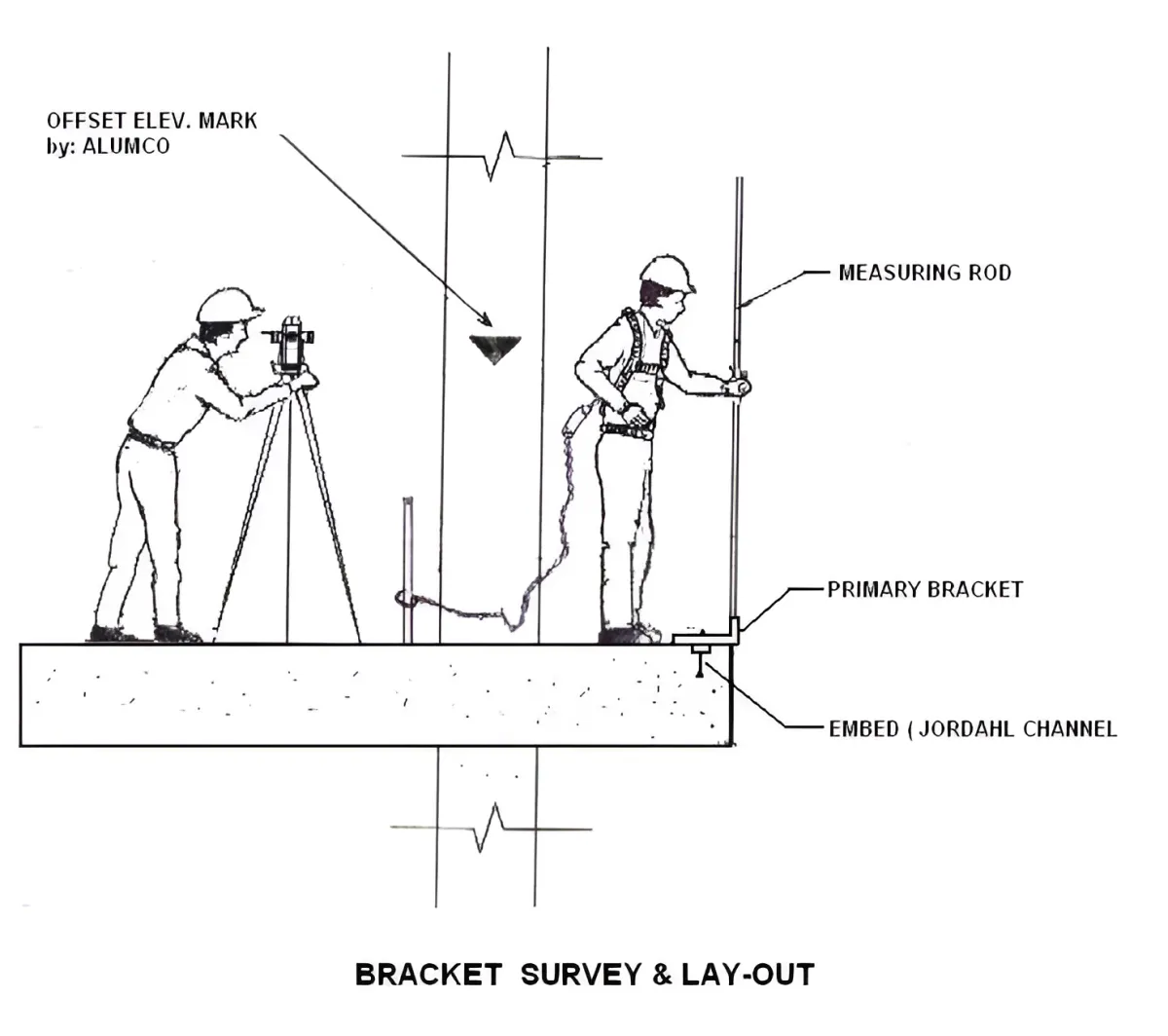

Installation Of Brackets

Surveyor For Site

4. Installation Of Bracket & Alignment Of The Bracket At Site

Alignment Of The Bracket

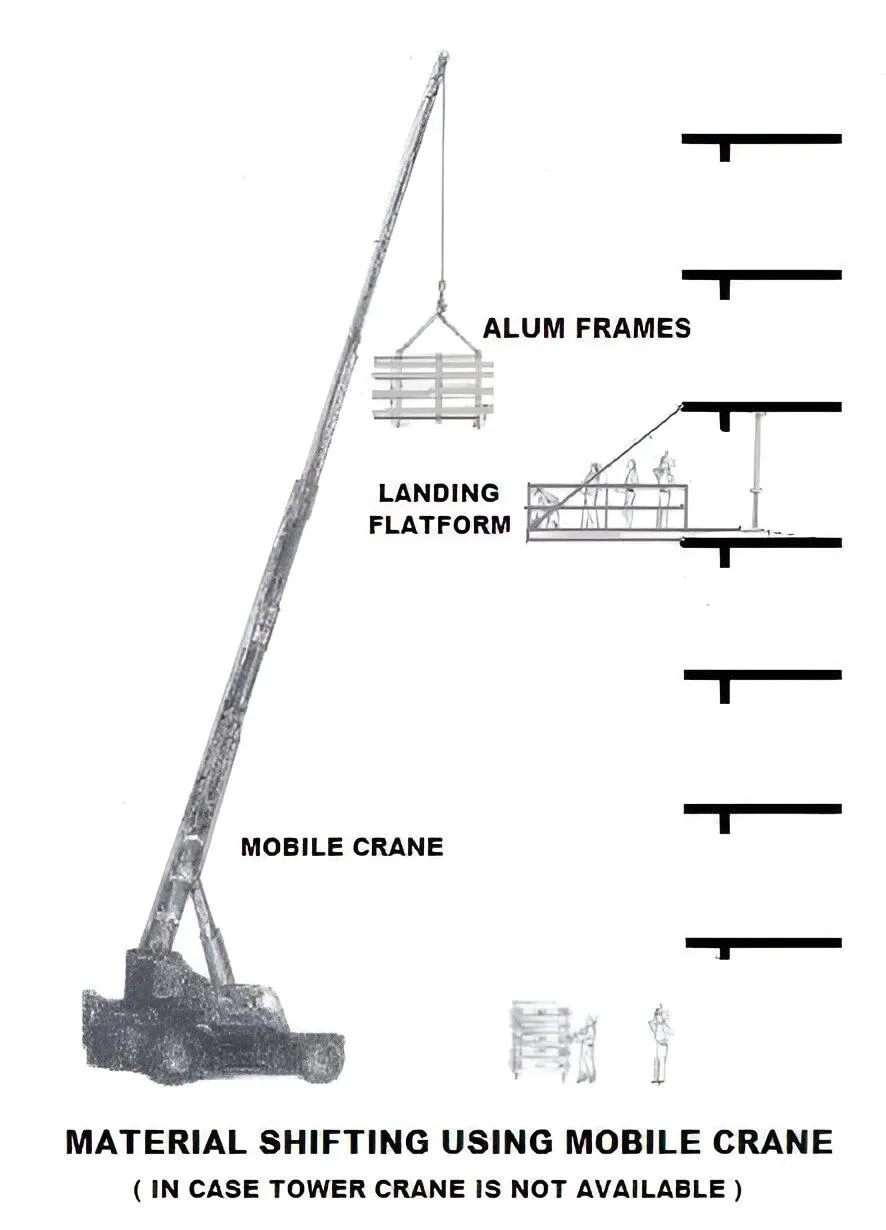

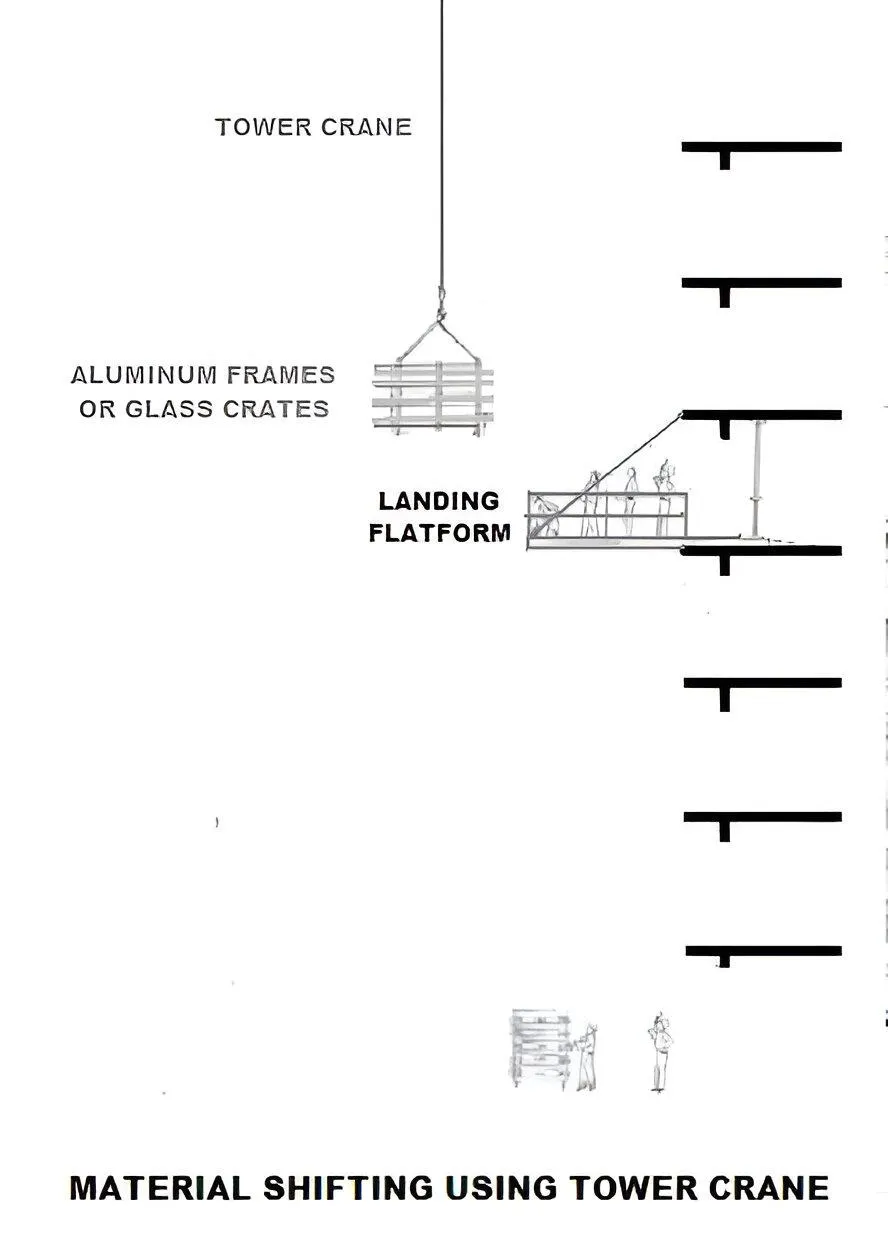

5. Using Tower Crane And Mobile Crane For Loading & Unloading

Mobile Crane To Be Used In Lifting & Shifting The Panel’s

Curtain wall panels shall be delivered on site in special fabricated transportation frames / pallets. It shall be stacked limited to five ( 5 ) panels high (maximum) with sub frames that act as inter layers. Each Sub frames are interchangeable and can stand alone except for the base. The base of each crate shall be provided with caster wheels for mobility and a sling hole which shall be used when lifting the crate to their designated storage area. Each crate are strapped and secured to avoid slippage and damage. From the truck bed the crates are fastened with a nylon lifting belt, then attached to the tower crane or mobile crane’s hook. With the signal of the crane riggers the crate are then lifted and safely landed on the ground or directly to the temporary staging area.

6. Receiving Deliveries On Site

7. Starting Installation Of Panel Upon Q.C Approval

Once the floor hoist is set to the required working area, same installation procedures using monorail shall be adapted except that in this method, the number of the panels that can be installed is limited upon the reach of the boom. The machine shall be relocated every time it finishes a certain area of installation. The boom shall be retracted temporarily while working being shifted through its wheel to the next working area. Observing all the safety precaution while being set.

Unitized Curtain Wall Facade

Elevation 1

Elevation 2

Elevation 3

Elevation 4

We are bound to continuous improvement and implementing appropriate quality management systems and processes to enable us to deliver the highest quality services.

Quick Links

Our Services

Contact Info

Location

Mussafah, Abu Dhabi - UAE